Syed Suhail

Sales Manager - Asset Managment

Tel: DXB +971 2 550 6868

Mob: +971 50 158 1076

Email: syed.suhail@kanoo.com

Asset protection & Preservation Solution

Kanoo offers VpCI (Vapor Phase Corrosion Inhibitors) preservation solutions for mechanical, static, rotary, and electrical equipment during transportation, storage, construction, and momentary or ongoing shutdown.

Kanoo offers mothballing solutions with Vapor Phase Corrosion Inhibitors (VpCI) to prevent corrosion in oil and gas, power plants, and manufacturing industries. The aim is to keep assets free from corrosion, making it cheaper to reinstate and use them. Corrosion is a major cause of equipment and asset downtime, especially in moist, salty air or changing humidity, leading to condensation on various components like electrical systems, machinery, and bolts.

Kanoo offers complete rig stacking solutions with Vapor Phase Corrosion Inhibitors (VpCI) for offshore jack-up rigs and land rigs in both cold and warm stacking conditions.

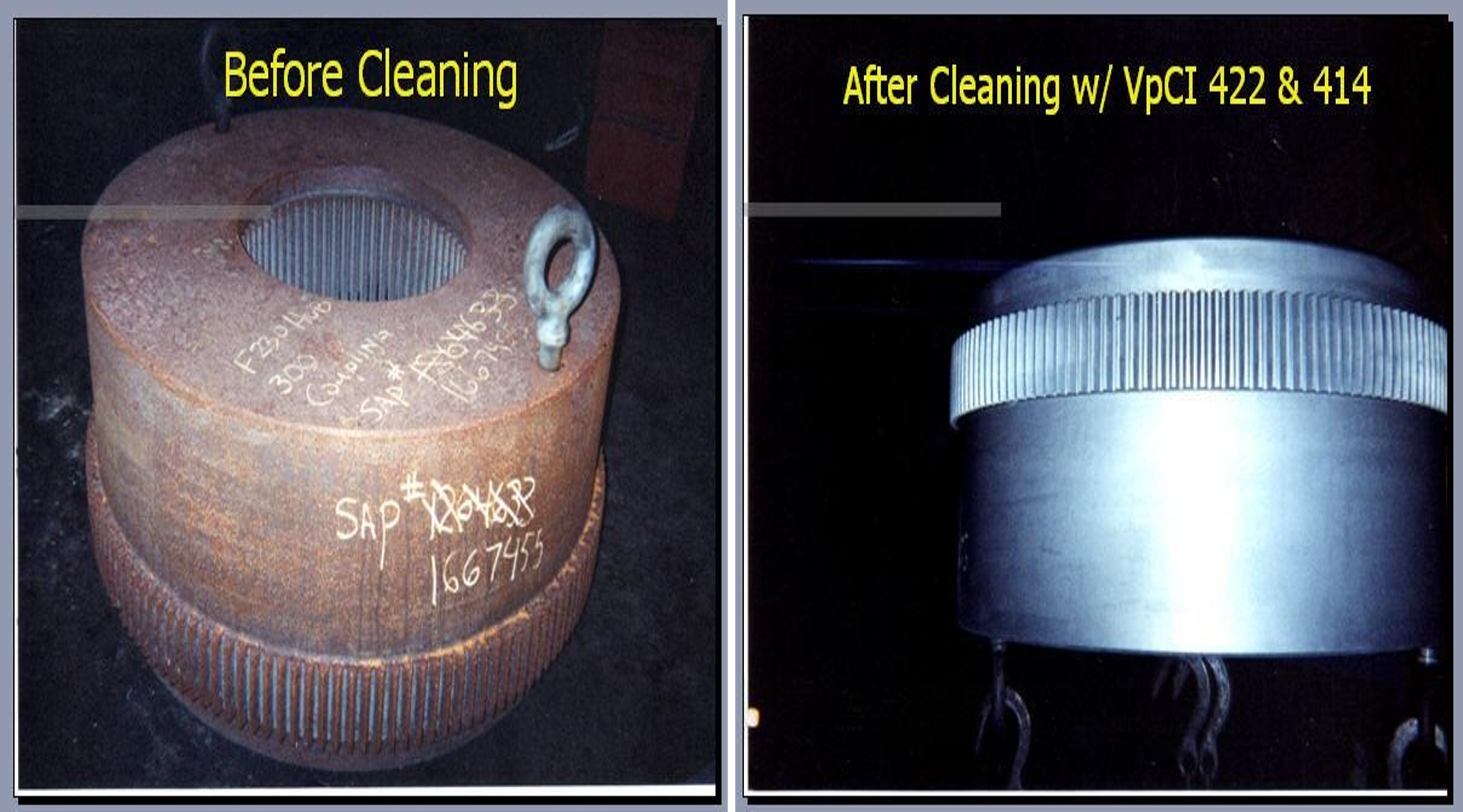

Kanoo offers VpCI (Vapor Phase Corrosion Inhibitors) rust removal products. These products are mostly organic, biodegradable, and non-hazardous, which sets them apart from harmful and toxic inorganic acid-based products.

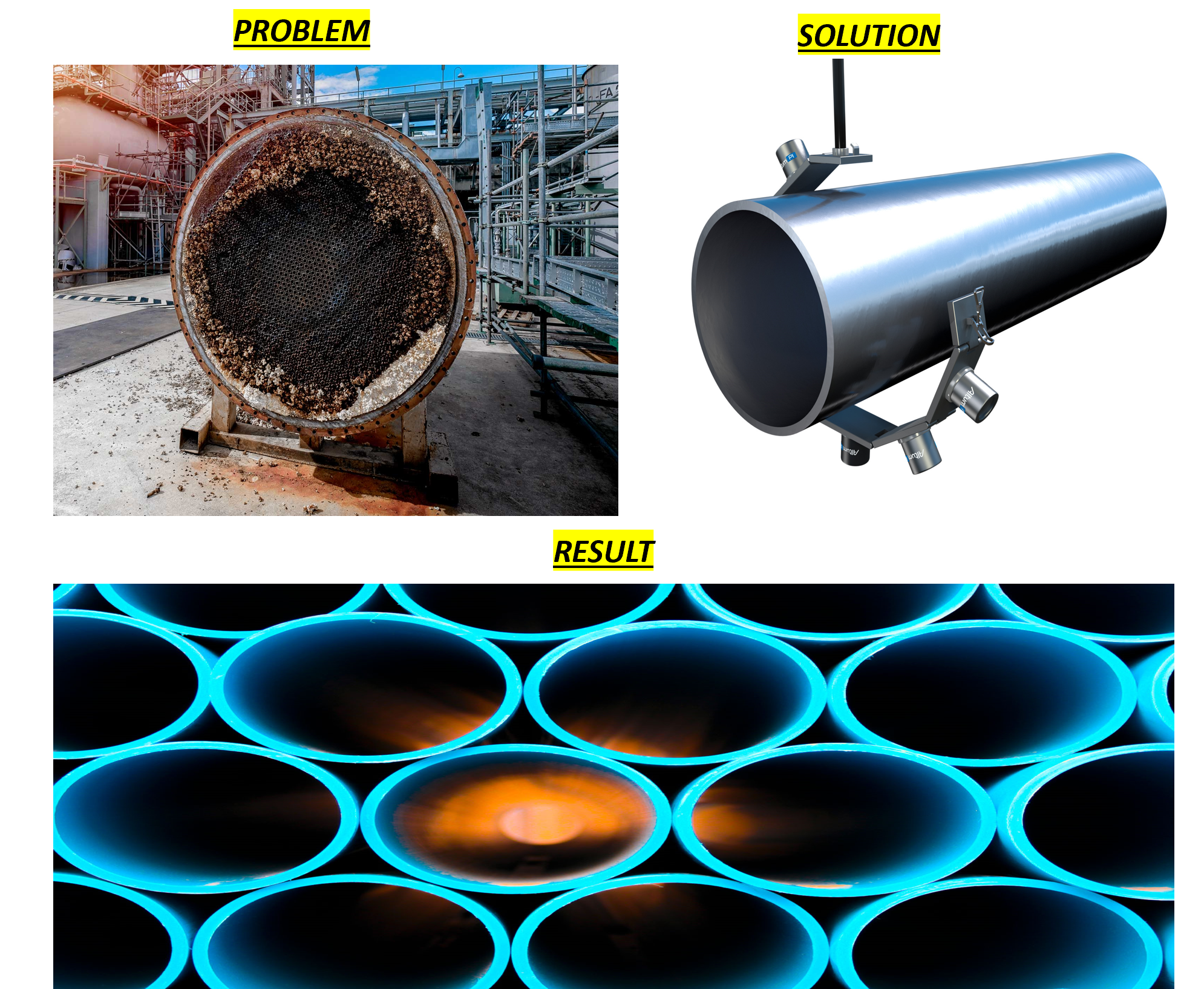

VpCI's heavy-duty degreaser/cleaners are effective in cleaning various components, including tube bundles with thick contamination from substances like oil or water, making them especially suitable for applications like lube oil systems, tube bundles, fin tubes, etc.

Kanoo offers VpCI (Vapor Phase Corrosion Inhibitors) corrosion protection coatings. The experts at Kanoo Energy assist in selecting the right product based on specific applications, whether for removable or permanent coatings. These coatings come in both water and oil-based options, designed to provide protection for short, medium, and long durations.

Kanoo provides VpCI (Vapor Phase Corrosion Inhibitors) solutions to protect the internals of offshore caisson platform legs.

Kanoo offers VpCI (Vapor Phase Corrosion Inhibitors) solutions as a secondary defense to safeguard the bottom plate of Above Ground Storage Tanks (AST) against corrosion from the soil side. This protective technology is applied at three different stages: during new construction, during shutdown (for major maintenance), and while the tanks are in use.

Kanoo offers comprehensive preservation solutions for various defense sectors, including the military, air force, and navy. These solutions involve implementing efficient asset integrity management systems, such as corrosion risk assessment and planning, corrosion studies, corrosion consultancy, and corrosion monitoring systems, which may include methods like coupons and ER probes.

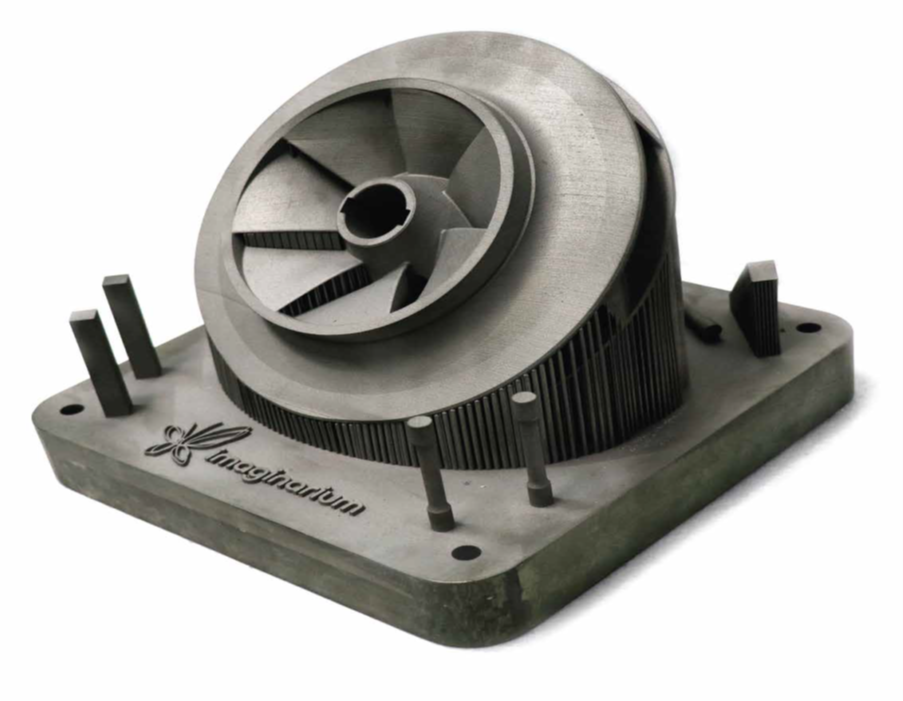

Reverse Engineering & Additive Manufacturing

Kanoo offers full digital library services, including the creation of digital inventories for spare parts. These inventories typically include high-value, critical, and obsolete components with long delivery lead times, often requiring minimum order quantities from OEMs.

Kanoo offers extensive reverse engineering services in 3D printing or additive manufacturing for any item, regardless of its shape or complexity. This process involves three key stages: implementation recovery, design recovery, and analysis recovery.